MarSurf

Contour and Surface Measuring Station LD-130

Please get a quote from us to purchase this product.

To get a quote please fill in the Enquiry Form :

- Select " Get A Quote " in Enquiry Purpose

- Fill in the product you would like to get a quote for under our "Message Field"

MarSurf UD 130

The MarSurf UD 130 closes the gap between the high-end solution MarSurf LD 13011D 260 and the new standard combination mea-suring station MarSurf VD140/280 with two probe systems.

The technical specifications of the MaiSurf UD 130 are based on theinterferometric probe system and the positioning speeds that reduce themeasuring time for each workpiece.

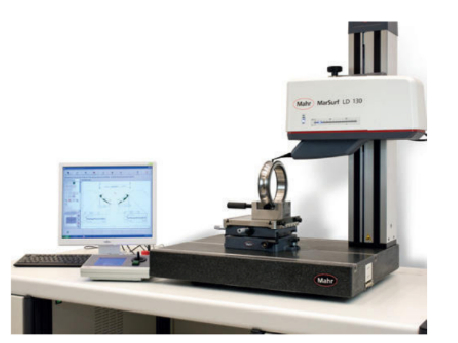

MarSurf LD 130 / LD 260. A step into a new dimension

Combined contour and roughness measurements in just one step comes courtesy of proven cutting-edge technology from Mahr metrology. The MarSurf LD 130 and Mar$urf W 260 measuring stations have been systematically developed to draw on the experience from the first generation of equipment.

- Roughness and contour in just one step

- High measuring and positioning speed cuts measuring times dramatically

- Innovative probe system removal

- Quick and reliable probe arm exchange with simultaneous probe arm detection by magnetic holder

- Long measuring length up to 260 mm (MarSurf LD 260) with a measuring stroke of 13 mm (100 mm probe arm length) or 26 mm (200 mm probe arm length)

- Modular construction for ease of maintenance

- No need to fully dismantle the measuring stand for maintenance

Supplied with:

- MarSurf XCR 20 including midrange LD, MarWin software Easy Roughness & Contour, Mahr license key

- TFT monitor

- MCP 21 manual control panel

- MarSurf LD 130 or LD 260 drive unit including LP D 14-10-2/60 LP D 14-10-500 probe system and probe arms

- Calibration standard for contour 1, accuracy class 1

- MarSurf ST 500 CNC measuring stand with 700 mm x 550 mm granite plate (induding control module)

- Dampening element set

- CT 300 XY table

Machine building

- Roller bearings, threads, threaded rods, ball screws, shafts, racks, ball heads, valves

Measurement close to the production area

- Contour and surface roughness measurement in semi-automatic and fully automatic operation

Automotive industry

- Engine parts including cylinder block, cylinder head, crankshaft, camshaft, valves, steering, gearbox, injection systems, turbocharger

Medicine

- Contour and surface roughness measurement for hip and knee endoprostheses, contour measurement for medical screws, contour and surface roughness measurement for dental implants

Optic

- Contour and surface roughness measurement of aspherical lenses

- ST 750 measuring stand

- Parallel V-block

- V-block, equipment table

- Measuring cabinet

- Extensive range of probe arms

Software options

- Profile processing

- Dominant waviness (WDc) for MarWin

- ISO 13565-3 surface parameters

- User defined parameters

- Topography

- Topography with Mf M

- Thread evaluation

- Chamfer evaluation (in accordance with Bosch standard)

- QS-STAT / QS-STAT Plus

- Digital I/O set